Advanced electrical system troubleshooting services for critical applications.

Advanced electrical system troubleshooting services for critical applications.

Blog Article

Leading Tips for Effective Electrical System Troubleshooting

Repairing electrical systems needs a systematic technique, grounded in a detailed understanding of electrical concepts and security methods. By familiarizing oneself with circuit parts, using important tools, and sticking to a structured analysis approach, specialists can effectively recognize and settle issues. The nuances of effective fixing expand beyond simple technological expertise; comprehending how to record findings and focus on safety and security can substantially affect end results. As we discover these important components further, it ends up being clear that mastering this process is not simply beneficial but crucial for success in the field.

Understand the Essentials

Comprehending the essentials of electric systems is essential for effective troubleshooting, as a solid foundation permits technicians to diagnose and deal with problems a lot more efficiently. A detailed understanding of electrical concepts, such as voltage, existing, resistance, and power, is important in recognizing the origin of issues. Voltage is the electrical possible distinction that drives current via a circuit, while resistance opposes the flow of current, impacting the total performance of the system.

Experience with circuit components, including resistors, capacitors, diodes, and switches over, is also vital. Each element plays a distinct role in circuit actions and can influence efficiency when malfunctioning. Additionally, comprehending collection and parallel circuit configurations is essential, as these setups affect the circulation of voltage and present within the system.

In addition, expertise of safety and security procedures is essential. Technicians should know prospective threats, such as shock and brief circuits, to apply risk-free troubleshooting techniques. By grasping these foundational ideas, specialists improve their ability to perform effective diagnostics and fixings, inevitably causing improved performance and dependability of electric systems. This foundational understanding is the keystone of successful fixing ventures.

Gather Necessary Equipment

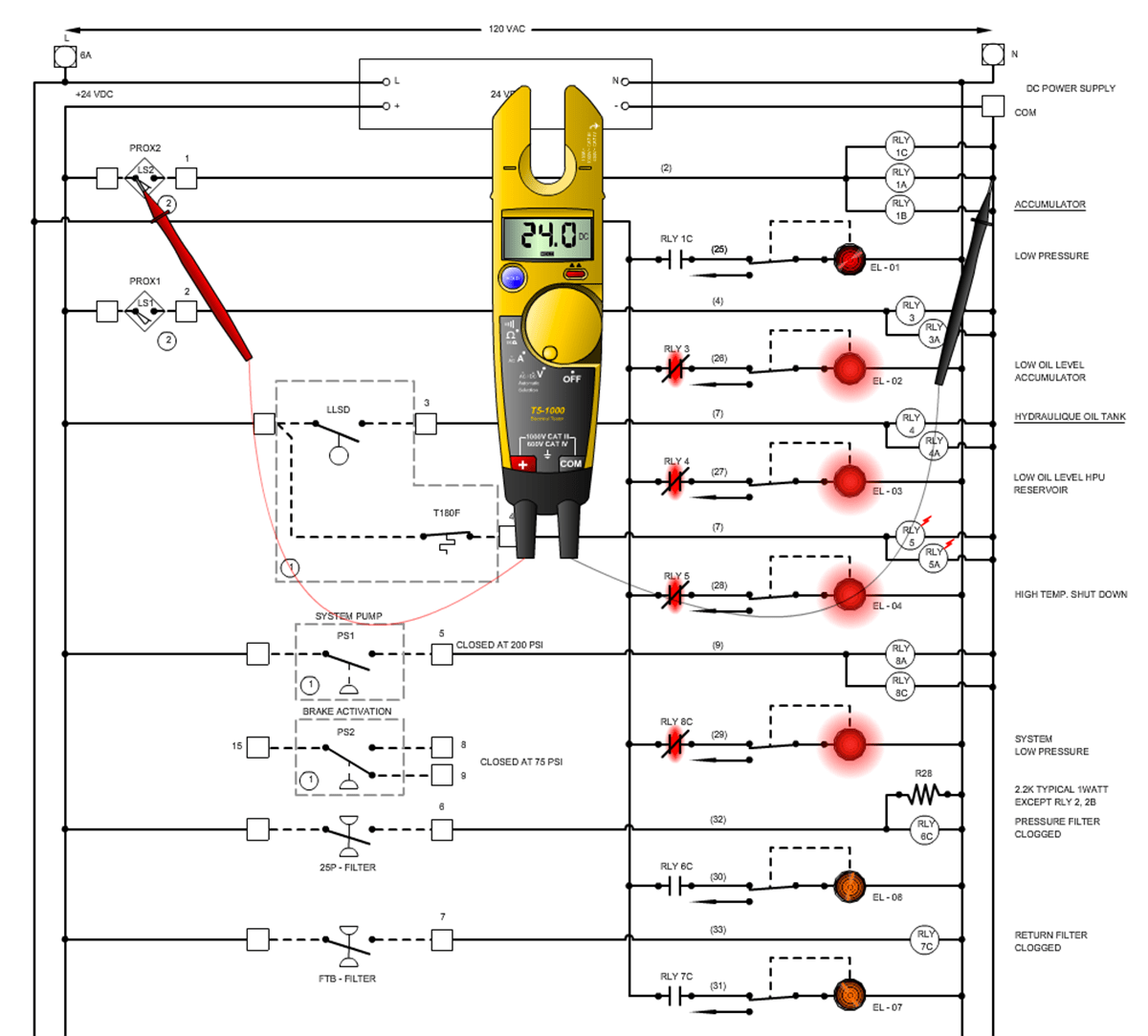

Effective troubleshooting of electric systems needs the best set of tools to identify and fix issues properly. A well-equipped specialist can considerably improve efficiency and efficiency in recognizing troubles. Important devices include a multimeter, which determines voltage, existing, and resistance, permitting accurate evaluations of electric components. Secure meters are additionally useful for measuring present without detaching the circuit, guaranteeing safety and security and comfort.

In addition, shielded hand devices such as screwdrivers, pliers, and wire strippers are critical for safely adjusting electrical links. It is additionally recommended to have a circuit tester on hand to confirm the existence of voltage in outlets and wires. For more complicated systems, a thermal imaging electronic camera can help find overheating elements, indicating potential failures.

Follow a Methodical Approach

Having gathered the proper devices, the following action in troubleshooting electrical systems is to adhere to a systematic strategy. A methodical technique makes certain that technicians can determine mistakes effectively and accurately, reducing downtime and preventing unnecessary repair work.

Begin by evaluating the system's schematic layouts and specifications. Understanding the design and operational parameters will certainly provide context for detecting issues. Next off, separate the issue location by utilizing a procedure of removal. This entails monitoring each element systematically, beginning with the source of power and working in the direction of the tons.

Utilize screening equipment, such as multimeters and oscilloscopes, to collect unbiased check here information concerning voltage, current, and resistance at numerous points within the system. This empirical proof will assist your troubleshooting initiatives and assist to verify or remove potential reasons of failing.

In addition, take into consideration environmental variables that might affect the system's performance, such as temperature variations or moisture access. A detailed examination of circuitry, links, and elements will guarantee that all possibilities are accounted for.

Record Your Searchings For

Complete paperwork is vital in the troubleshooting process of electrical systems. This technique not only help in comprehending the root reason of the problem yet also serves as a referral for More Bonuses future fixing initiatives.

Furthermore, maintaining a log of parts changed or fixings done is vital. This information sustains supply monitoring and can help examine the long life and dependability of particular parts.

Inevitably, the paperwork process must be extensive yet succinct, enabling simple retrieval and review - electrical system troubleshooting. By focusing on comprehensive paperwork, professionals can produce a valuable knowledge base that not only aids in present troubleshooting however additionally equips future maintenance efforts, thereby improving overall system reliability

Prioritize Precaution

Recognizing the intrinsic dangers related to electric systems is crucial for ensuring safety during troubleshooting. Electric shock, burns, and equipment damages are just a few of the potential threats that specialists encounter. Focusing on security actions is not only a lawful responsibility however also a moral imperative that safeguards both the technician and the surrounding setting.

Prior to commencing any type of troubleshooting job, service technicians need to put on ideal individual protective tools (PPE), consisting of protected gloves, shatterproof glass, and flame-resistant garments. Guaranteeing that the work area is dry and cost-free of clutter can significantly decrease the risk of crashes. It click to read is important to de-energize circuits prior to beginning any work, validating that they are not live through the usage of a multimeter or voltage tester.

Establishing clear interaction protocols with employee is likewise important; this ensures that everybody understands potential threats and the status of the electrical system being dealt with. Having an emergency situation response plan in location can verify vital in the event of an event. By focusing on precaution, specialists can efficiently minimize risks and cultivate a safer office.

Verdict

Efficient electric system repairing counts on a thorough understanding of essential principles and a systematic strategy. Focusing on safety actions ensures the health of people involved and the stability of the electrical system.

Report this page